Non-Destructive Testing Machines

SPECIAL CELLS CND

Customer Needs

To meet the A350's increased production rate, to reach 1 part controlled

3 min on a 900 parts scope including 600 different parts (without series effect).

3 min on a 900 parts scope including 600 different parts (without series effect).

VLM Robotics cell

Cartesian ultrasonic NDT machine

Agile robot (part recognition, recruitment and positioning in the thickness measuring tank)

CN (C-scan and traceability).

CN (C-scan and traceability).

Machining Cells +

SPECIAL CELLS FOR MULTI-FUNCTION MACHINING

Customer Needs

Robotic applications for pre-machining of hard materials or finishing operations with fine tolerances in space reflector molds.

VLM Robotics Cell.

Nimitech's multifunctional machining cell for workpieces (up to 4 m in diameter).

Robot KR360, NC, Divider, Tool changer, routing…

Robot KR360, NC, Divider, Tool changer, routing…

Additive Manufacturing Cells +

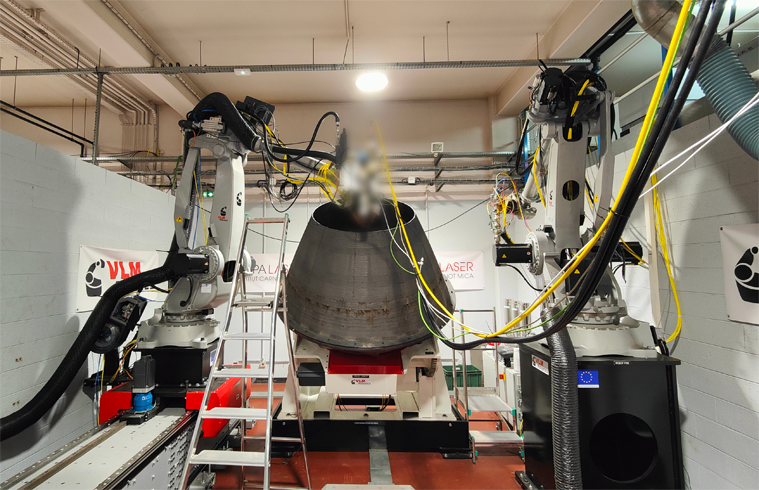

GEMINI: ALM XXL Bi-Robots Cell

Customer needs

Additive Manufacturing of XXL Metal Part with Control in Process

from wire and powder for the cooperative society IREPA-LASER

Gemini cell prepared in DED by VLM-Robotics

DED powder and wire cell for parts (H: 5 m * Diam: 2 m)

2 robots including one potentially for control in process

2 linear axes (5 m), 1 2-axis turning table (3 tons)

piloting by NC Direct Control and NX Software

10 Effectors DED and embedded controls

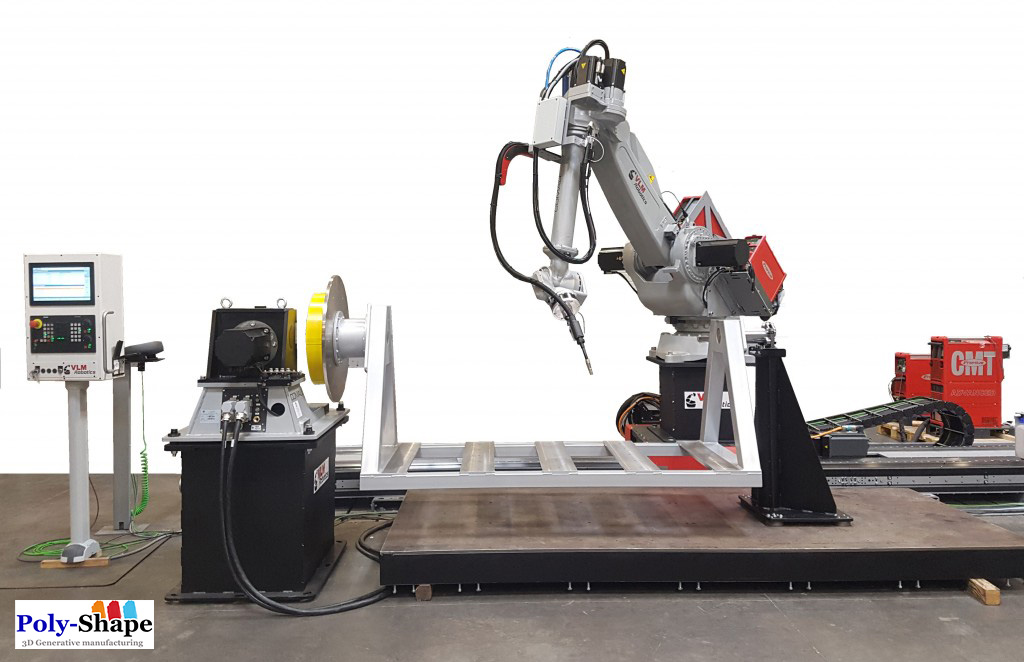

SOLO : special cells ALM XXL

Customer Needs

Additive manufacturing of XXL large metal partsfrom wire for an additive manufacturing service provider.

VLM Robotics Cell

WAAM & Plasma cell for metal parts of 6m x 2m x 2m Robot, 6m linear axis, 2-axis (9 axes) turning device controlled by a NC in Direct Control.

NX Software

Dual Wire Fusion Technologies: CMT & Plasma.

NX Software

Dual Wire Fusion Technologies: CMT & Plasma.

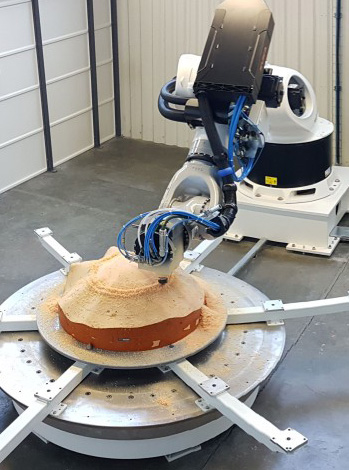

COMPAQT : Standard Machine ALM XL

Market Need

From the special XXL metal additive manufacturing machine ...

to the standard XL machine associant la by combining the most mature WAAM wire technologywith la simplicité d’utilisation the ease of use of a CNC-controlled robot.

To meet the various industrial requirements: ASD, Rail, Naval, Energy, MRO, Foundry, Tooling… as well as Training and Research organizations.

to the standard XL machine associant la by combining the most mature WAAM wire technologywith la simplicité d’utilisation the ease of use of a CNC-controlled robot.

To meet the various industrial requirements: ASD, Rail, Naval, Energy, MRO, Foundry, Tooling… as well as Training and Research organizations.

Machine Compaqt VLM Robotics

ALM for XL part (Ø600 H600 weight <500kg)

7 axis machine : Robot, rotary table, CMT Advanced system.

Control via NC in Direct Control, integrating NX software and Mindsphere connection.

Machine prepared for in-process monitoring.

Turnkey packaged solution.

7 axis machine : Robot, rotary table, CMT Advanced system.

Control via NC in Direct Control, integrating NX software and Mindsphere connection.

Machine prepared for in-process monitoring.

Turnkey packaged solution.

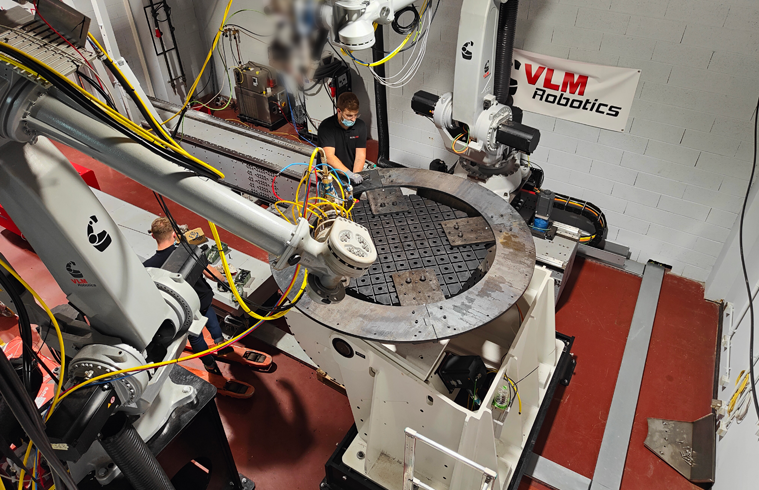

Control in Manufacturing Process

Market Trend

Whatever the industrial applications, control during the manufacturing process is a means of real-time agility.

The demand is therefore evolving towards cells that mix machining and control or manufacturing and NDT or several manufacturing steps in strong interdependence: cleaning and bonding ...

The demand is therefore evolving towards cells that mix machining and control or manufacturing and NDT or several manufacturing steps in strong interdependence: cleaning and bonding ...

VLM Robotics Solutions

Single or multi-channel (several robots) Direct Control NC configured cells allowing the implementation of closed loops as well as a fine control linked to a high capacity and speed of information processing.

Gemini: MANUFACTURING XXL Bi-Robots Cell

Customer needs

Manufacturing XXL with Control in Process or Hybrid

Gemini cell VLM-Robotics

2 robots including a potentially control in process

2 linear axes (10 m), 1 2-axis turning table 3-20 tonnes

Controlled by a NC Direct Control and NX Software

Manufacturing Effectors: Machining, Bonding, Control, Additive Manufacturing, NDT, Post or Pre Processing, Maintenance, Handling ...

VLMV3T TURNING MACHINE: 2-axis 3-ton turning machine

Available in higher tonnage on request Driven by NC in Direct Control Play compensation and precision